The iSCAN series of portable 3D dimension measuring instruments are professional precision

measurement devices based on structured light scanning technology using binocular stereo

machine vision to capture the three-dimensional geometric features of objects. iSCAN series

achieve precise measurement for the features on the surface, e.g. the step difference of surface

concave and convex, the depth and the width of surface pits, the width of joints, the depth and

length and width of surface scratches, and other geometric information.

Weighing only 2kg, the portable 3D scratch dimension measurement instrument allows one-click measurement to obtain scratch width, depth, step height and seam width, by capturing 3D point cloud data with an XY resolution of 6.7μm and Z

resolution of 0.2um.

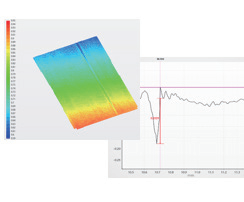

Scratch

Measurement

With the iSCAN measurement

software, users are able to

measure the width and depth

of scratches in a selected

area using manual or automatic methods.

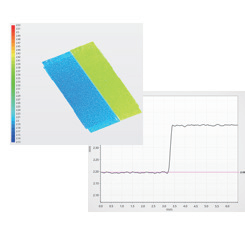

Step Height

Measurement

With the iSCAN measurement

software, users are able to

measure the step height in

a selected area using manual

or automatic methods.

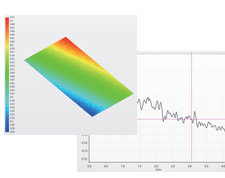

Seam

Measurement

With the iSCAN measurement

software, users are able to

measure the step height in

a selected area using manual

or automatic methods.

Portable

Measurement

The probe of iScan weights

less than 2kg making it easy to

perform handheld measurements in various locations.

Fixed

Measurement

iSCAN obtains point cloud data

with 5 million points in less

than 1 second per measurement.

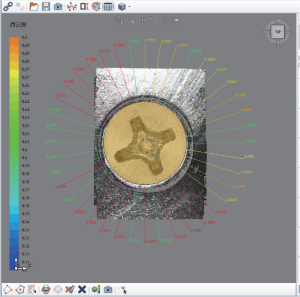

Automatic

measurement of

rivet head heights and

counterbore depths

iSCAN achieves automatic

batch inspections of screw

and rivet head heights and

counterbore depths on aerospace assemblies.