IMS Quality Data Collection & Management System

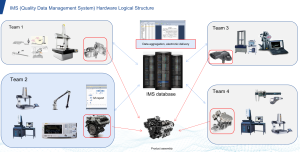

IMS Quality Data Collection Management System enables the connection of various measuring tools, instruments, and inspection equipment via wired/wireless means, facilitating automatic data acquisition (IoT). The collected data is then stored as structured data for efficient management and analysis.

It supports the automatic generation of electronic inspection reports and the approval management of reports. At the same time, the system also supports data archiving, traceability query, production process quality analysis (SPC analysis), quality monitoring, output statistics, pass rate statistics and other data management functions.

The IMS system realizes the data collection, data integration, data analysis and data traceability of quality inspection data. Data collection is the first step of achieving Industry 4.0 and it plays a crucial turning point in the digital management of enterprises. Data analysis is the beginning of enterprise intelligence, and the accumulation of data will be the most important wealth that enterprises cannot be replaced in the future and cannot be made up for.

Efficient information collection system enables cross-departmental and cross-factory monitoring, management, and utilization of monitoring data; enhances the convenience, security, authenticity, and consistency of data; improves efficiency in measurement and quality data management, reducing production costs; and minimizes human errors and unexpected losses in measurement and processing processes.

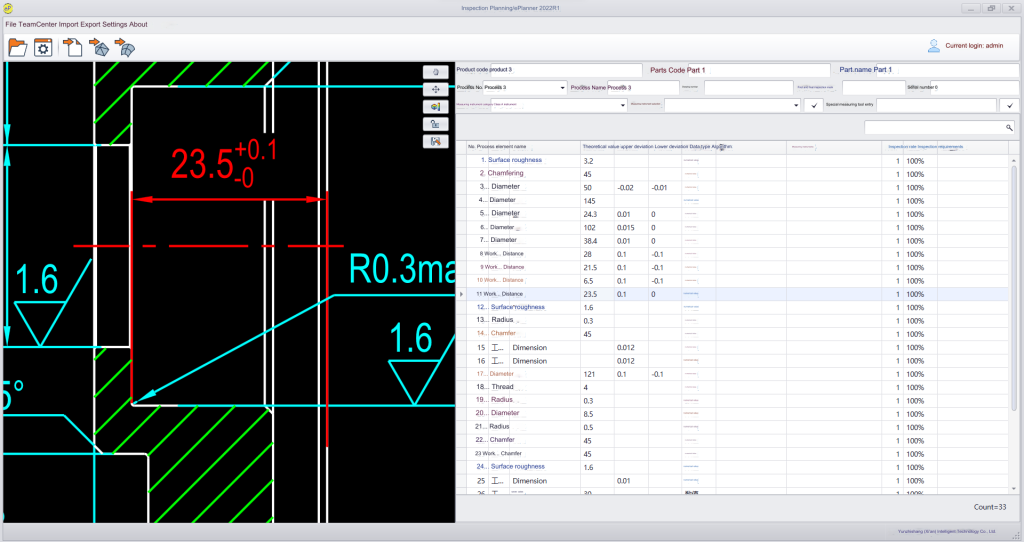

Quality control planning

Formulation of inspection plans, assignment of inspection tasks, establishment of product inspection standards, and unified management of inspection task scheduling.

Gauge data collection

Automatic collection of manual gauge data; automatic drawing navigation; out-of-tolerance alert for measurement data; automatic storage and statistical analysis of measurement data.

Instrument data collection

Automatic collection of data from most mainstream inspection equipment; analysis and processing of measurement data; automatic

storage and statistical analysis of measurement data.

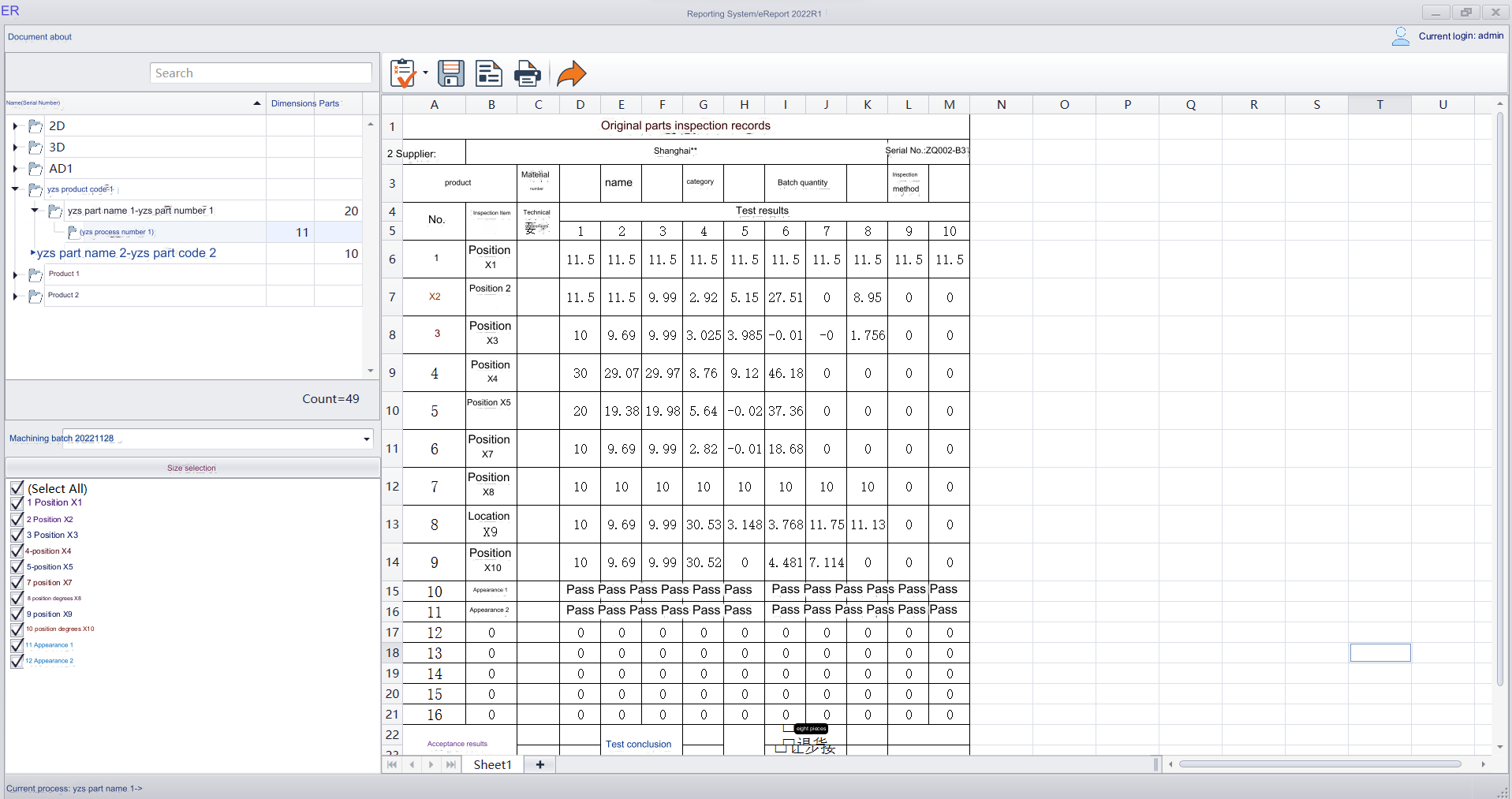

Quality data reporting

Flexible adaptation to different report templates; automatic aggregation of data to generate reports; report viewing and approval; automatic report distribution.

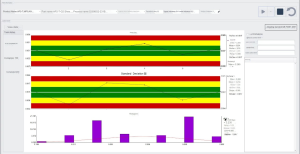

Quality data analysis

Supports SPC control charts (histograms, run charts, mean-range charts, etc.); calculates common statistical parameters (mean, standard deviation, range, etc.); real-time SPC, real-time monitoring; facilitates statistical report output.

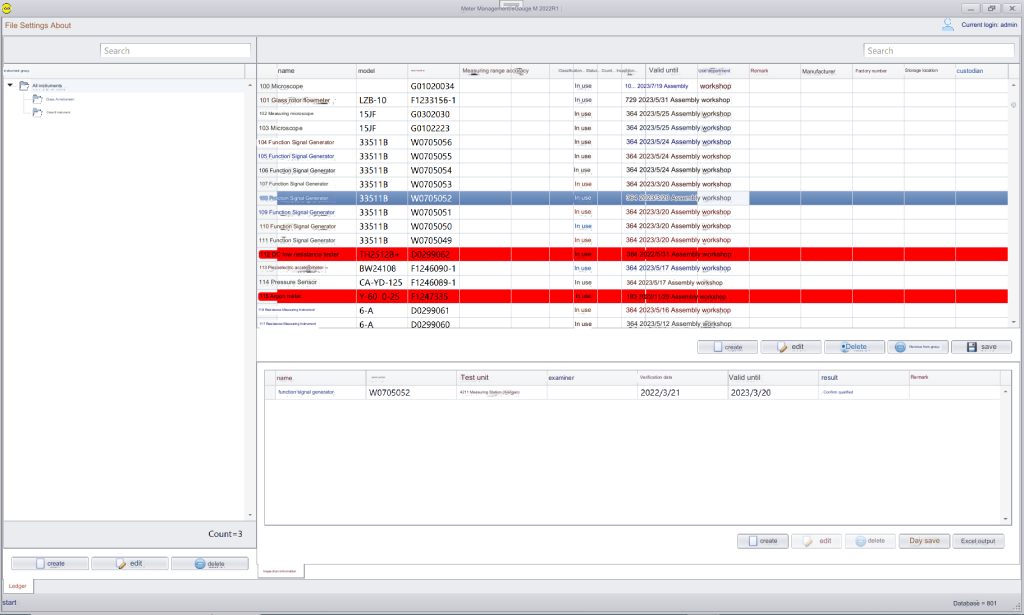

Instrument and equipment

management

Unified management of instruments and equipment, establishment of instrument and equipment ledger, calibration management,

maintenance management, repair management, and upkeep management.