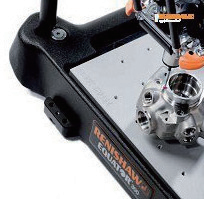

The YZS Equator combines the advantages of Renishaw equator gauging system and PC-DMIS software to form a flexible gauging system. The YZS Equator provides high-speed, repeatable, and user-friendly measurement solutions for both manual and automated measurement applications. It achieves the control of manufacturing process, by offering the workshop with highly repeatable, temperature-independent, versatile, and reprogrammable comparator measurement solutions.

The YZS Equator executes PC-DMIS programs on the Equator gauging system, and conveniently extends three-coordinate measurements to the production site.

– Diameter –

– Cylindricity –

– Flatness –

– Angle –

– Position –

– Straightness –

– Roundness –

– Concentricity –

– Perpendicularity –

Automatic Measurement

By interfacing with robots or machine tool controllers, the YZS Equator system enables

automate measurements, eliminating human errors and improving production efficiency.

High-speed Measurement

Thanks to its unique parallel structure, the YZS Equator achieves much higher measurement speeds compared to traditional coordinate measuring machines.

Replacement of Traditional Gauges

By utilizing coordinate measurement technology, the YZS Equator measures workpieces with few restrictions when various features are measured conveniently.

Gear Measurement

With the help of eGEAR module developed specifically for gear measurement, the YZS Equator enables rapid and batch measurement of gears on the Equator gauging system.

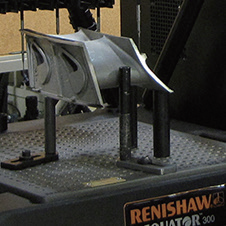

Blade Measurement

By utilizing the eBLADE module developed specifically for blade measurement, the YZS Equator facilitates rapid and batch measurement of blades on the Equator gauging system.

Bearing Measurement

By utilizing the eBEAR module developed specifically for bearing measurement, the YZS Equator facilitates rapid and batch measurement of bearings on the Equator gauging system.